MECACONCEPT SOLUTIONS

TAYLOR-MADE INDUSTRIAL SOLUTIONS

Innovation has always been part of MECACONCEPT's DNA. With its multi-sector experience, MECACONCEPT stands out for its ability to provide concrete answers to the most diverse industrial problems.

Every day, in Canada and in France, MECACONCEPT employees combine their skills to provide efficient and flexible industrial solutions. At MECACONCEPT, we are committed to offering you equipment that meets your expectations today and evolves with your needs tomorrow.

Sébastien NIVET, CEO of MECACONCEPT

EXAMPLES OF TAYLOR-MADE SOLUTIONS

USE-CASEIn this section, you will find customer success stories that illustrate various industry issues

AUTOMATED HANDLING OF LARGE METAL SHEETS

TECHNICAL SUPPORT

Home furnishings industry

- Manual handling identified as a source of MSD²s and potential accidents

- These manipulations mobilize 2 operators 50% of the time.

- This workstation is considered to be a bottleneck in the growing production flow.

- Gather technical input data (product characteristics, speed, work environment constraints, etc.)

- On-site visit to identify obstacles and opportunities for implementation

- Definition of technical specification

- Technical writing of the project

- 3D design of a preliminary project

- Proposal of an estimated budget (89000 CAD)

- Assistance in the evaluation of the return on investment (ROI of 2.38 years

HANDLING AND LOADING ROBOTS MACHINING EQUIPMENT

TAYLOR-MADE EQUIPMENT

Building Industry

- Automation aging

- Need to increase production capacity

- Application de Pick and Place application with SCARA robot (FANUC) combining speed and precision.

- Loading/Unloading application of machining centers by 6 axis robot (FANUC)

- Part tracking with 2D vision system (Fanuc)

- Custom design of electromechanical gripping and intermediary jig

- Taylor-made gripper embedded on a 6 axis robot for load/unload operations

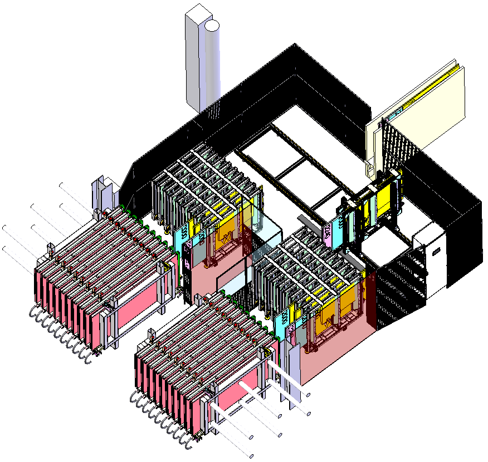

LINE AUTOMATION

AUTOMATION REDESIGN

- Increase productivity during the day (1 operator was no longer enough)

- Produce automatically at night shift if necessary

- Replacement of Mitsubishi automation (obsolete) by a fully SIEMENS architecture. PLC S7-1500 with servodrive S210, Brushless motorization SIEMENS 1FK

- Opening to PC world through Production Order Managment - ERP interfacing - dynamic vision of the line status, C# development

BE SPOKE SOLUTIONS

TO KNOW MORE